Manufacturing Process: Produced using an automatic manufacturing line that incorporates:

- Automatic Forming: Ensures precise shaping of finwalls.

- TIG Welding: Provides strong, clean welds for enhanced durability.

- Spot Welding: Guarantees superior aesthetics and structural integrity.

- Horizontal Bending: Correct bend formation without deflection.

>> Decoiling – Forming – Embossing – Welding – Cutting – Bending – Varnish – Packing – Dispatch

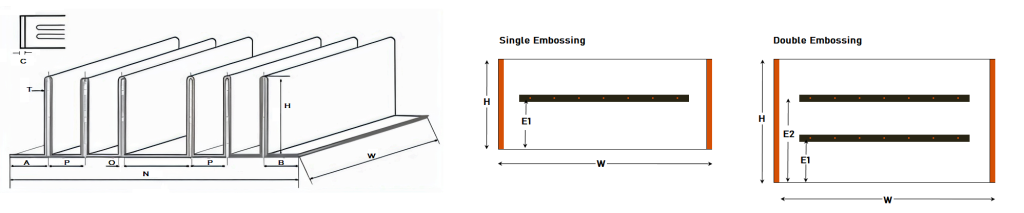

| Finwall Width [min-max] | W | 300 – 1600 mm |

| Finwall Height [min-max] | H | 50 – 400 mm |

| CRCA Thickness (MS, SS) | T | 1.0 – 1.5 mm |

| Pitch [between two fins] | P | 40 – 80 mm |

| Oil Duct | O | 6 – 8 mm |

| Front, Rear Edge | A, B | 25 mm |

| Reinforcement Strip | C | 10 – 20 mm |

| Embossment & Spot Welding | Required | Yes / No |

| First Embossing Distance | E1 | 70 / 90 / 110 / 130 / 150 / 170 / 190 / 210 / 230 / 250 mm |

| Second Embossing Distance | E2 | 190 / 210 / 230 / 250 mm |

If you have any special requirements, please get in touch: info@visionexim.in.

#corrugatedtransformertank #corrugatedfinwalltransformer #corrugatedfinwalltank #transformer